Manufacturing

Program Description

Advanced manufacturing consists of Manufacturing I and Manufacturing II. For students who like to work with their hands and enjoy finding out how things work and how things are made, this is the course for you! Our goal in the manufacturing program is to have our students experience all facets of the manufacturing industry.

Level I

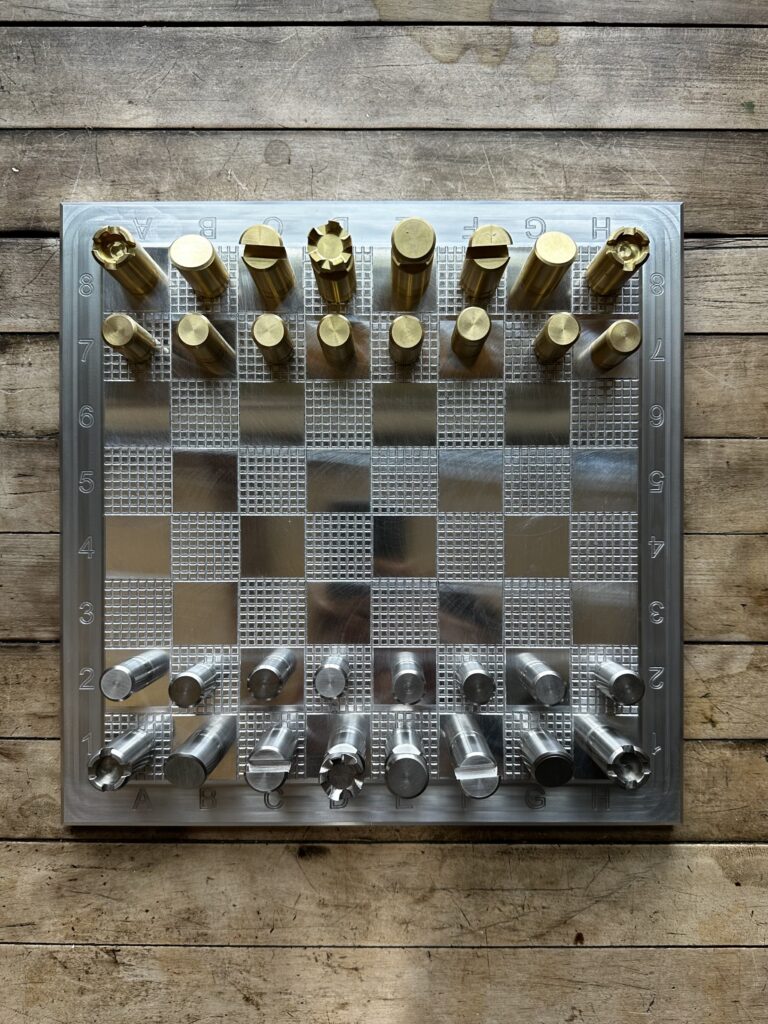

Students will be introduced to and have the opportunity to explore machining, welding, sheet metal, 3D printing, CAD/CAM, and CNC programming. Students will also be able to develop their artistic side in our blacksmith shop. Manufacturing I is a project based class where students are encouraged to design and build projects of their choice. Students will have the opportunity to earn college credits in our dual enrollment program along with multiple industry related credentials.

Level II

Students will be able to focus on and enhance the skills they were introduced to in Manufacturing I. Solidworks, a CAD industry standard, will be taught for a semester two days weekly. Students will have the opportunity to receive a certification in Solidworks which is an industry-recognized credential. Students will also be furthering their skill-generating toolpaths with advanced CAM software. Students will be encouraged to develop, and design projects of their choice using all the tools available to them in our manufacturing lab.

For more detailed information go to our Program of Study.

Clubs and Activities

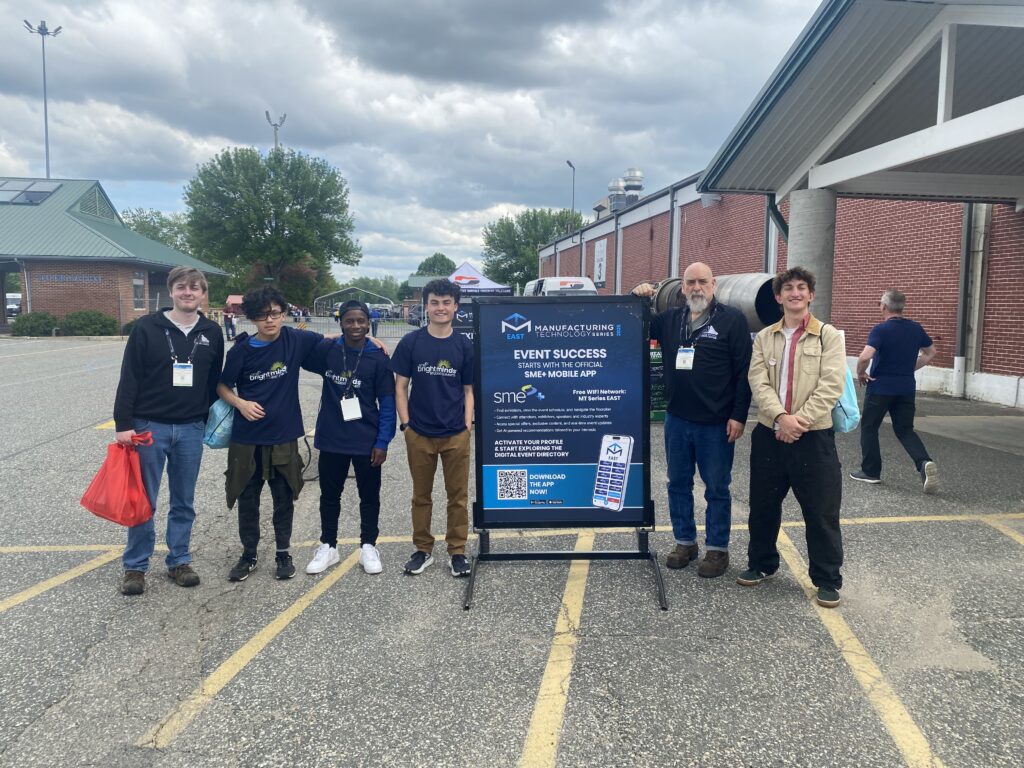

SKILLS-Preparing for leadership in the world of work.

SkillsUSA is a United States career and technical student organization serving more than 395,000 high school, college and middle school students and professional members enrolled in training programs in trade, technical and skilled service occupations, including health occupations.

SkillsUSA is a partnership of students, teachers and industry working together to ensure America has a skilled workforce. SkillsUSA helps each student excel. Skills provide education programs, events and competitions that support career and technical education in the nation's classrooms.

Industry Recognized Credentials

Career Safe OSHA 10

National Institute of Metalworking Skills

Your Instructor

Richard Thompson

I've been in the industry for forty years. I have owned a contract manufacturing business and currently still own and operate a small prototype shop.

I was looking for a new opportunity and had stumbled across an advertisement for this teaching position and thought I would like to try it. I'm heading into my third year and I'm pretty darn happy!